Advantages of UP3d P53 5 axis milling machine compared to other brands:

- 24/7 support even on holidays and weekends at no charge. We guarantee that UP3D engineers can answer your questions anytime.

- True 90-degree vertical milling for more aesthetic dental anatomy especial in the anterior.

- CAM and CAD software updates are always free.

- Better cost/performance ratio

- Consumables such as burs and spindles cost less so the operating cost in the long term is more reasonable.

- Free spare parts for the first two years.

- The UP3D system including UPCNC and UPCAM nesting is smarter and more digital than the VHF family of products.

- Airfare rebate to visit the UP3D training center in California: if you want to visit the UP3D training centre in LA, we will reimburse you the travel ticket expense of up to $600 if you decide to purchase a P53 milling machine.

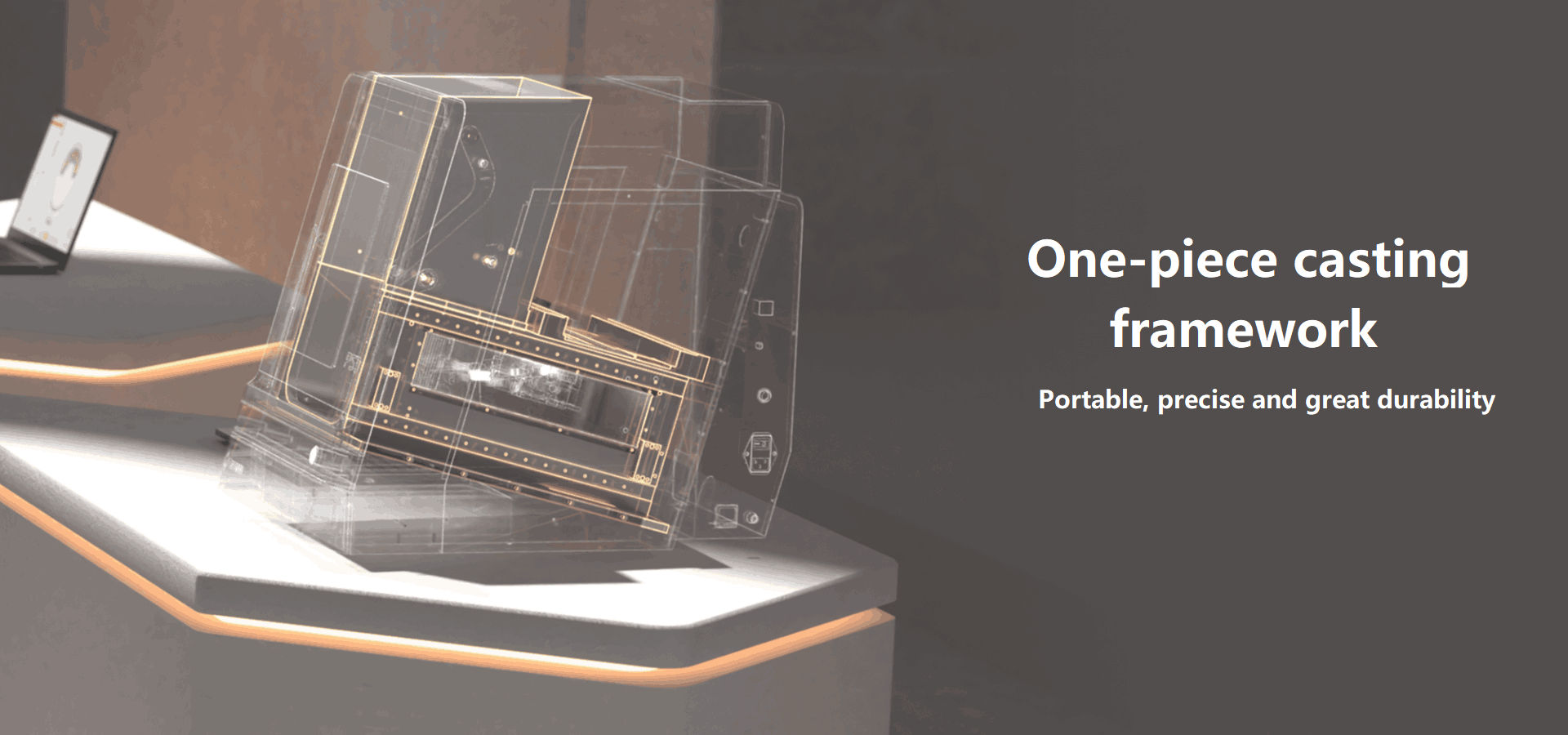

Automatic calibration

and great durability

Smart Dental Milling Machines

WE ARE

FULL DENTAL CAD/CAM

SOLUTION

DEVELOPER AND

MANUFACTURER

UP3D is a high tech company headquartered in Shenzhen since 2013.

UP3D is one of the few companies in the world that are capable of developing a full dental CAD/CAM solution including software and hardware.

We are committed to provide our worldwide customers with high quality dental CAD/CAM products to benefit from the digital dental revolution.

UP3D-digital technology improves life

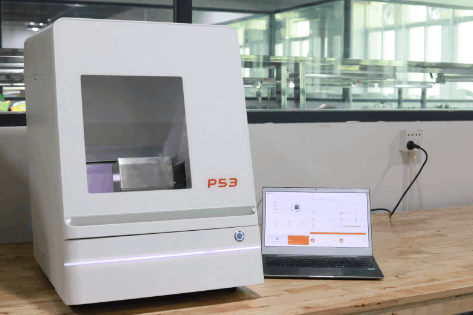

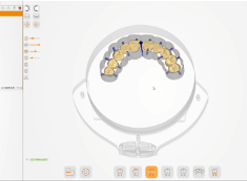

P 5 3

5-axis

milling

machine

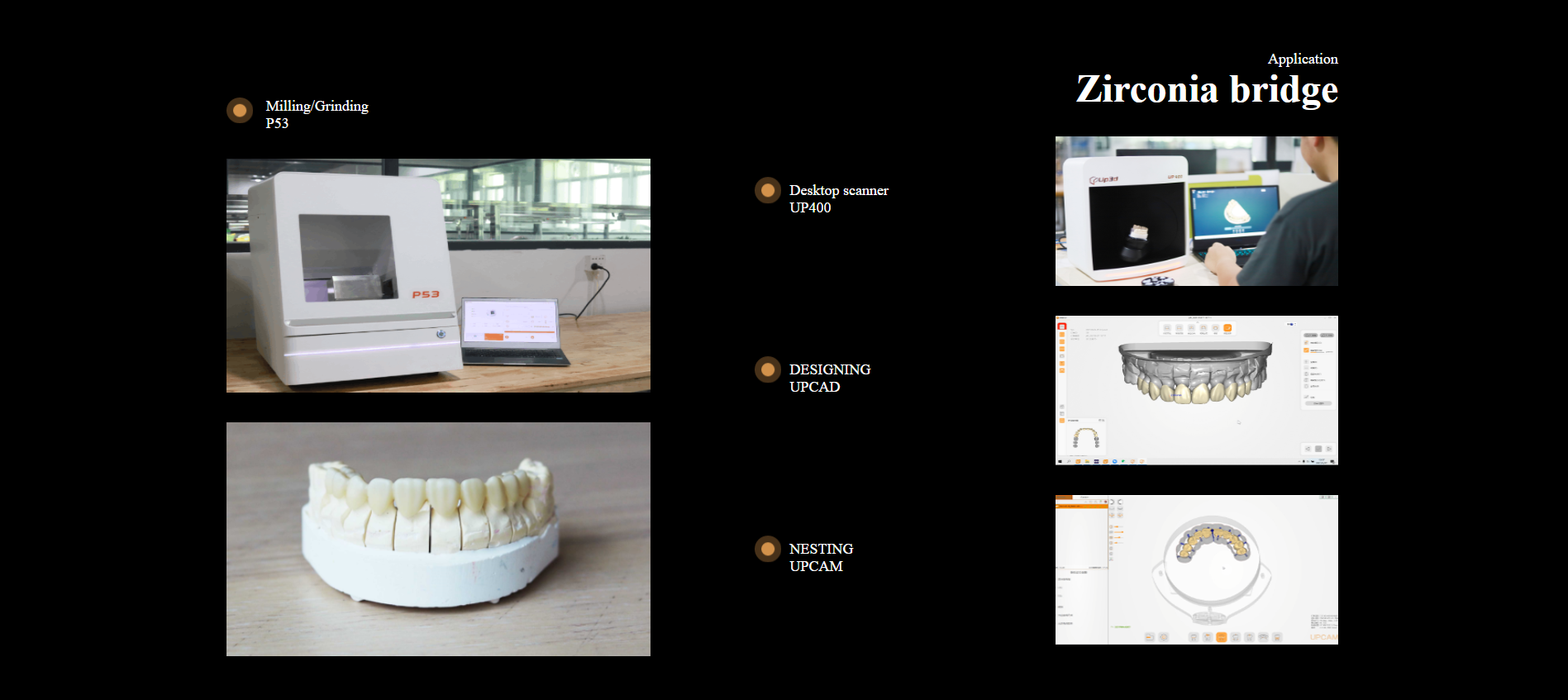

Full CAD/CAM hardware and software are developed by UP3D

All software and hardware are independently developed by UP3D with core technology, intelligent control system and a perfect combination of integration.

Simple installation

IY installation,only 10 mins.

Intelligent initialization

The first milling machine with fully automatic calibration and intelligent initialization in China.

Remote connection

One platform controls full process machines, and enables to real-time monitoring the production status of multiple machines.

RESUME

All software and hardware are independently developed by UP3D with core technology, intelligent control system and a perfect combination of integration.

LED light progress bar

Machine will display the processing progress. Reduce personnel inspection time.

SPECIFICATIONS

Model | P53 |

Dimension | 443.5×718×628.5 ( m m ) |

Weight | 87Kg |

Input voltage | AC 185~235V 、 50~60Hz |

Max power | 0.8KW |

Spindle power | 0.52KW(max) |

Axis | 5-axis simultaneous motion |

Milling range | X/Y/Z : 170/215/105mm A : ±30° B : 360° |

Milling mode | Dry milling |

Max rotate speed | 30,000rpm |

Max feed rate | 3000mm/min |

Tool library | 11 |

Tools changing | Automatic ( Air pressure >0.5MPa ) |

Spindle cooling | Air compression ( Air pressure 0.25~0.35MPa ) |

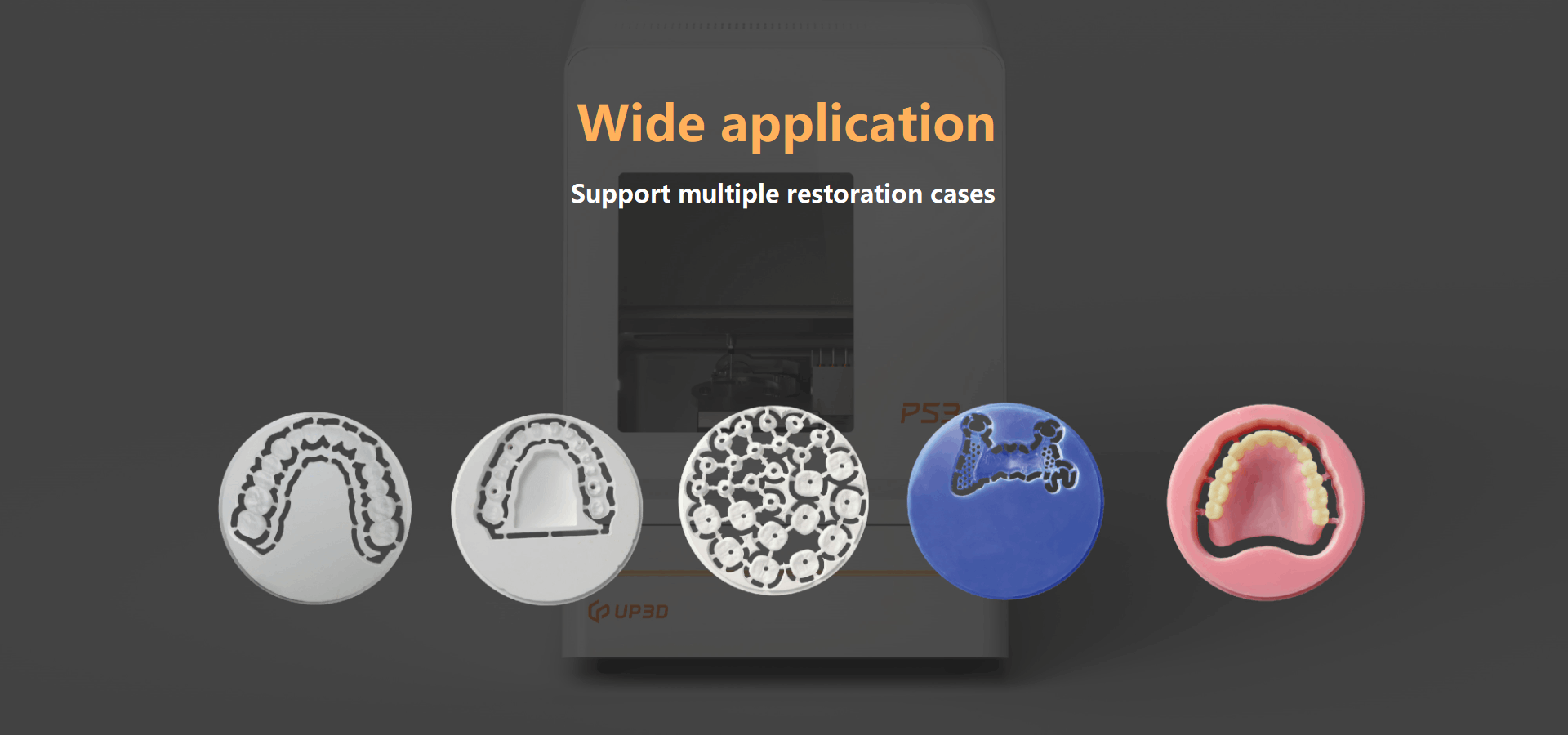

Milling materials | Zirconia, Wax, PMMA, PEEK and soft materials |

Milling time | Coping : Zirconia-10min Wax- 4.5min |

Crown : Zirconia-13min Wax-5.5min | |

Tools diameter | 2+1+0.6 ( Φ 4 ) |

Reviews

There are no reviews yet.